The Future of Quality Inspection

Illuminated by Hybrid Lighting

Illuminated by Hybrid Lighting

About

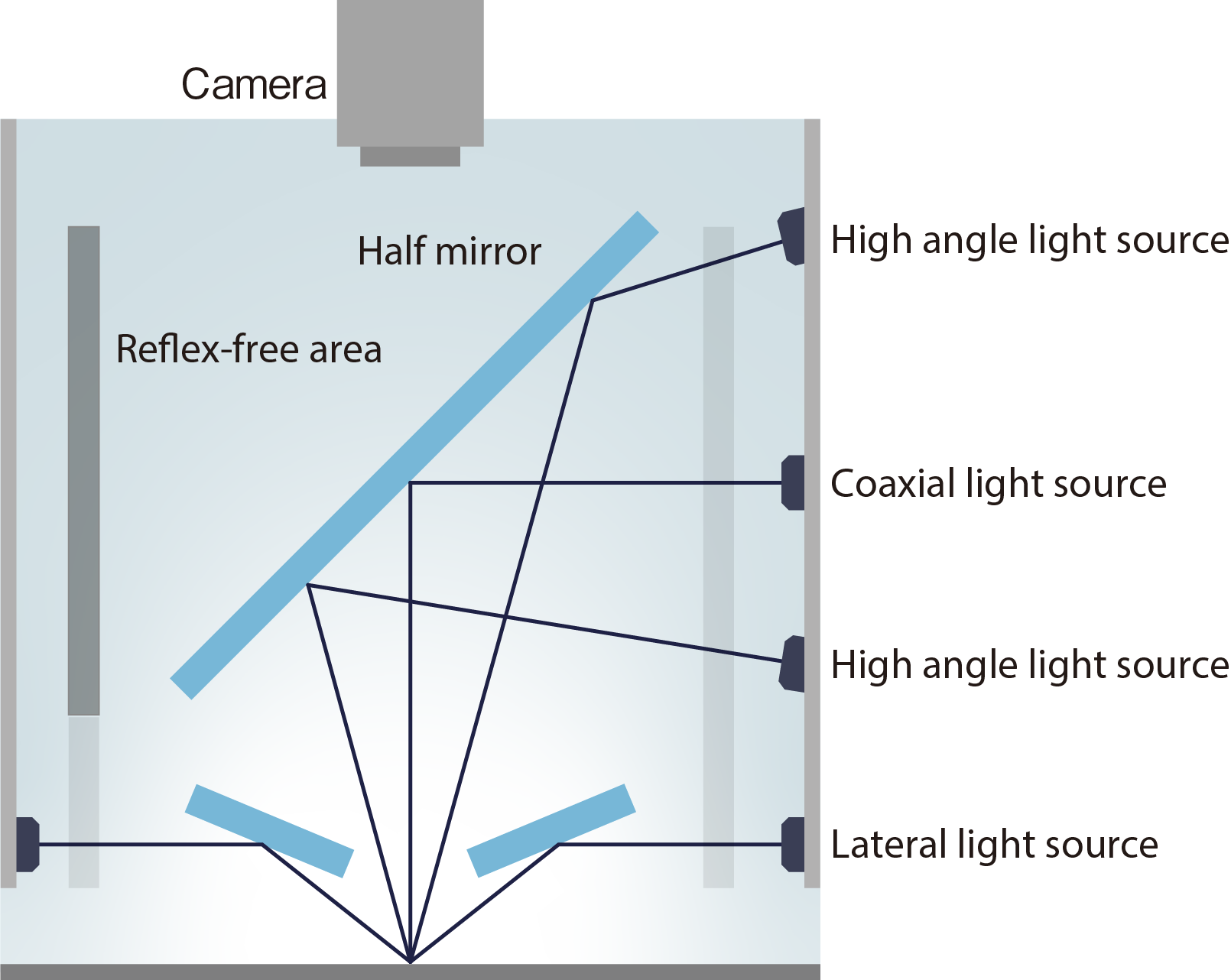

Basics of Hybrid Lighting

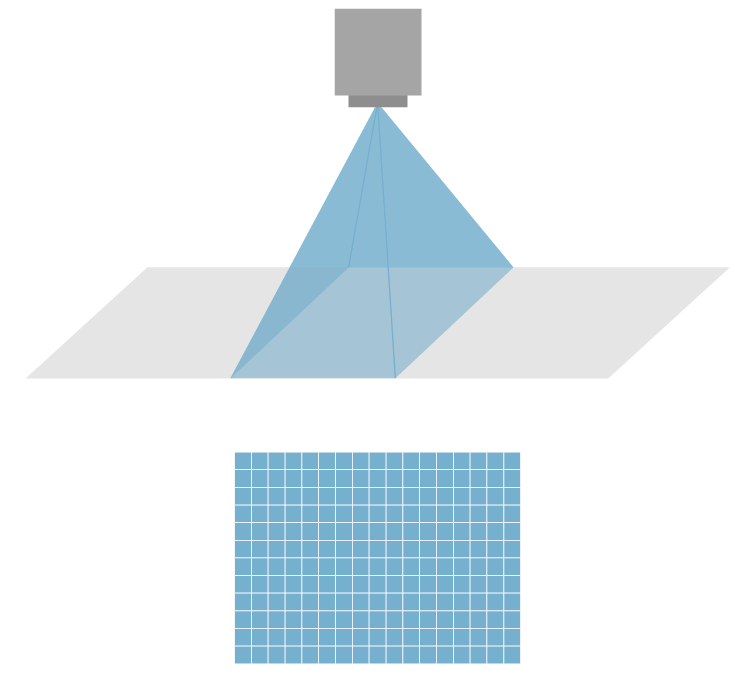

The lighting on the workpiece is an important factor in image inspection to ensure the detection of dirt, scratches, etc., while maintaining both quality and production efficiency, and to prevent the leakage of defective products.

In general, the detection of small scratches on objects which are highly reflective (ex., metals and mirrors) is difficult by one direction lighting.

Therefore, by irradiating and blending light on the workpiece from multiple directions instead of one direction, it is possible to detect tiny scratches on metals and mirrors.

Features

Pros of Hybrid lighting

The power supply developed specifically for hybrid lighting is possible to generate 100 times the power of lighting for general area sensor cameras.

Since the on-board multiple and multi-directional lighting can be electronically controlled, the system can flexibly respond to various work environments and configurations.

Features

- Tens to hundreds of times more powerful than general area sensor camera lighting

- Includes coaxial illumination, high-angle illumination, and lateral illumination in a single lighting block

- Electronic control of the brightness in each illumination

- Lighting that brings out minute scratches on metal and mirrors.

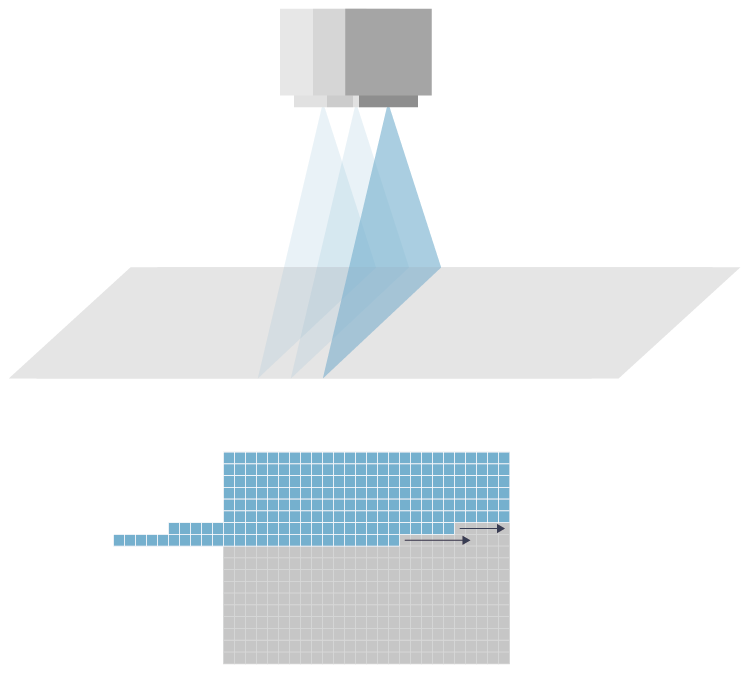

Hybrid lighting blends pictures from high angle, coaxial and lateral illumination angles to reduce surface roughness and enable stable inspection.

Which makes it possible to detect small scrapes on surface that are difficult to capture with a single light source.

-

High angle light source

- Less reflected light (insufficient brightness)

- Smaller contrast between rough and flat areas

-

Coaxial light source

- Flat surfaces are bright (sufficient brightness)

- Rough surfaces are captured darkly

- Large contrast between rough and flat areas

-

Lateral light source

- Surfaces are imaged dark(insufficient brightness)

- Large amout of reflected light in rough areas

- High contrast between rough and flat areas

Blending photos with different lighting source

Solutions

Issues to be solved by hybrid lighting

01

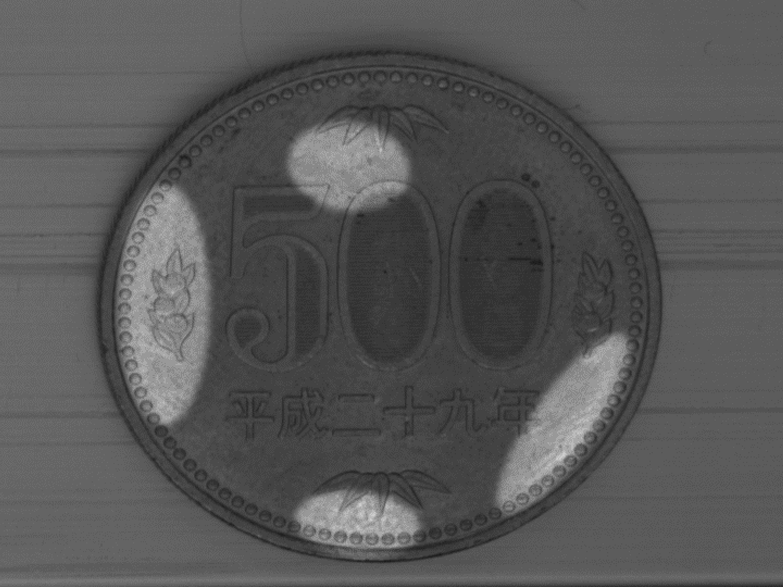

Objects with high reflectivity

By blending light from multiple directions, small scratches on objects such as metals and mirrors can be detected.

Under normal light source

|

Under hybrid lighting

|

|

Hairline, which appear under normal light source, have been eliminated by adjusting the brightness of each angle of the hybrid lighting. On the other hand, it is also possible to take a photo that brings out the hairline. |

|

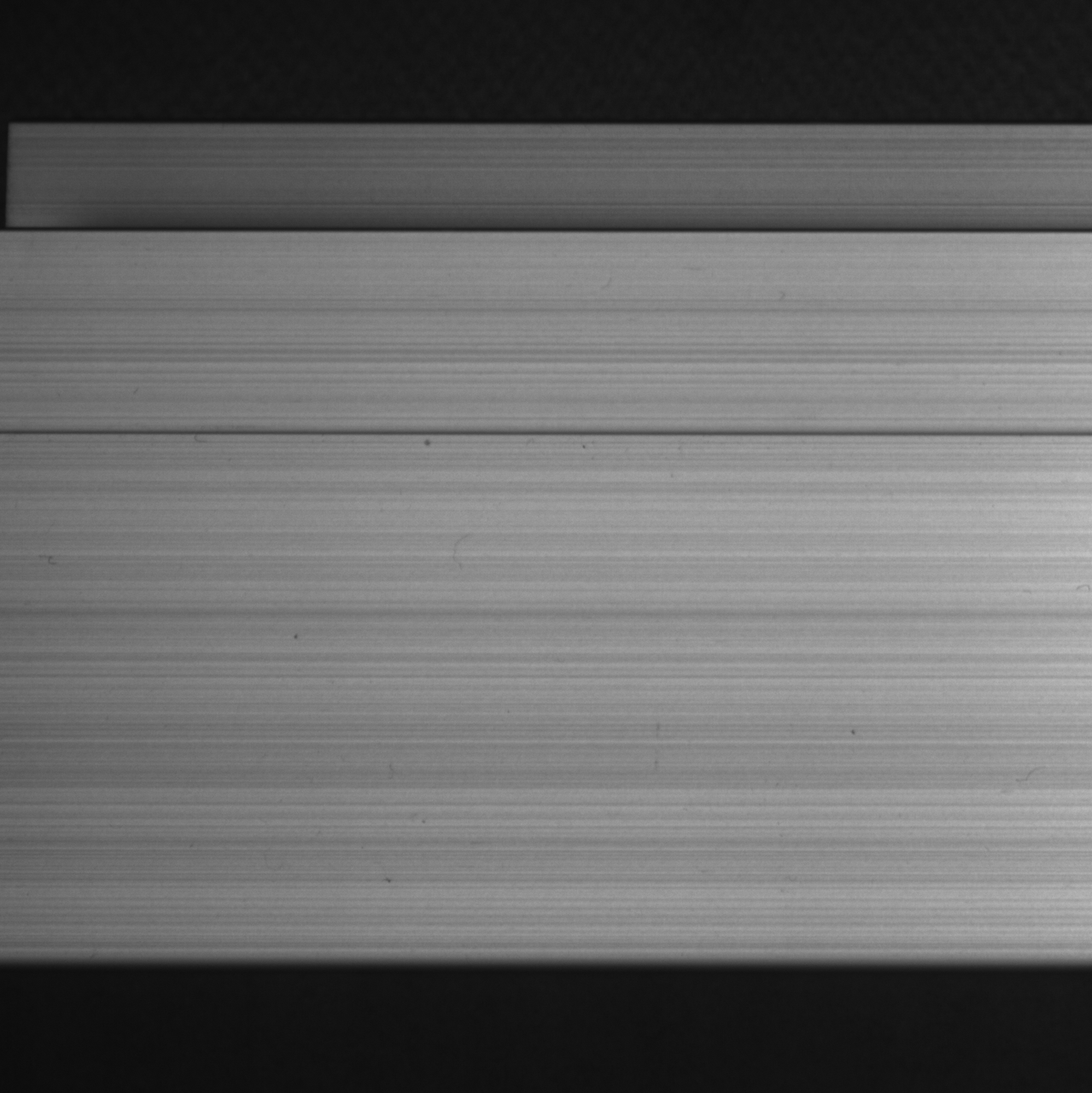

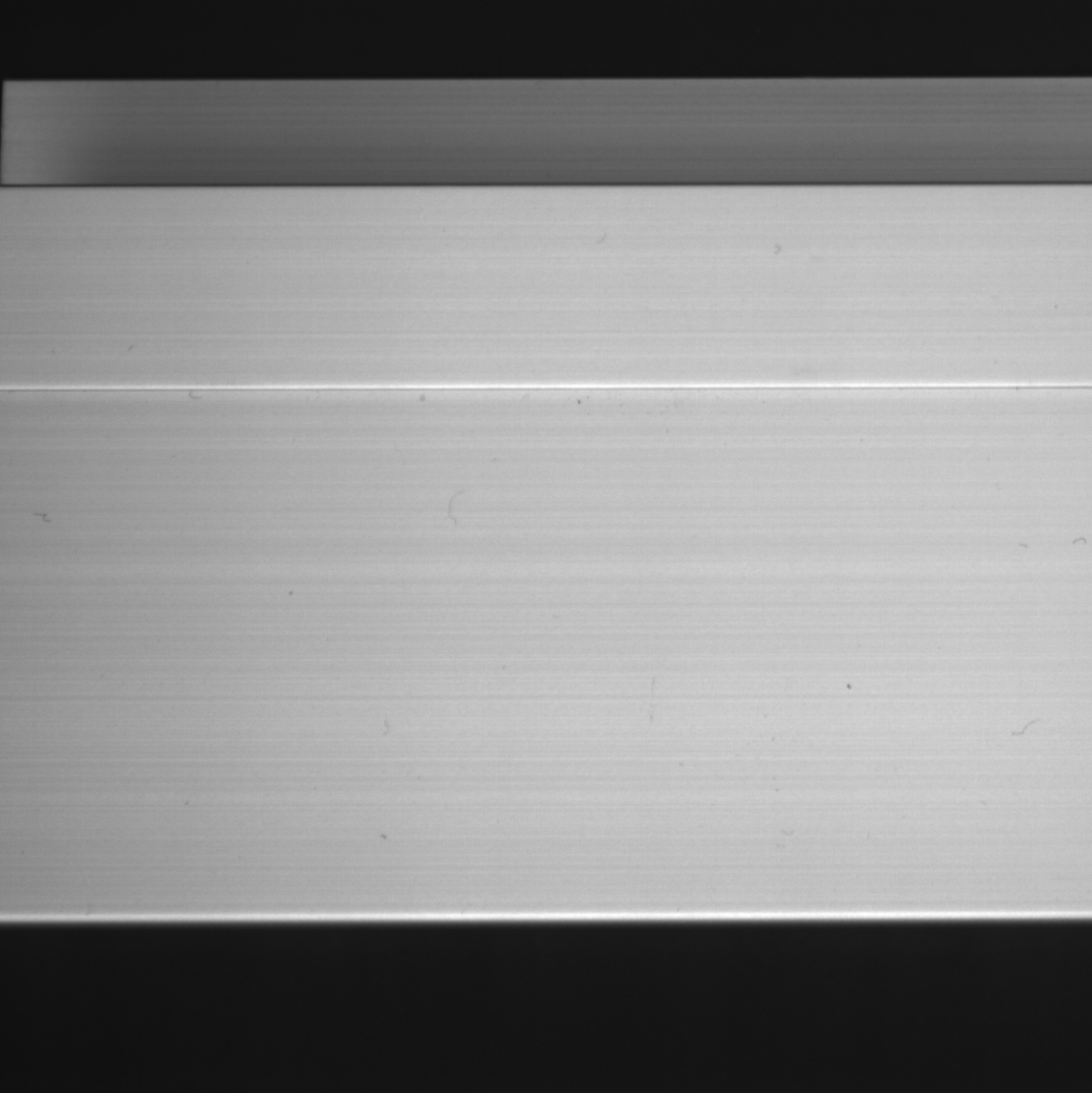

02

Very small scratches and scrapes

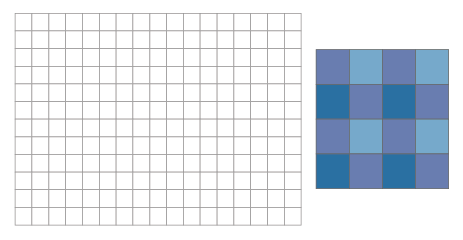

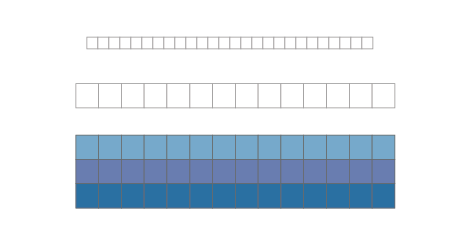

Line cameras can only capture a linear area at a time, houwever, offer much higher image quality than area cameras.

The hybrid lighting we develop is designed for line camera photography.

Area camera

|

Line camera

|

Structure

|

Structure

|

|

1,280 x 760 (Normal resolution) 1,920 x 1080 (High resolution) |

8,000 x 1 (Normal resolution) 16,000 x 1 (High resolution) |

| 1/30s exposure time |

1/50,000s exposure time(Normal condition) 1/100,000s exposure time(Fast SS condition) |

|

|

03

Object with large roughness

High-intensity illumination of about 400W, which is about 100 times brighter than the illumination for general area cameras.

Since sufficient exposure is possible, the aperture of the lens can be narrowed to the limit. This makes it easier to focus than with conventional cameras and allows the entire workpiece to be photographed in fine detail.